BASICS OF CHISELS

the birth of chisels

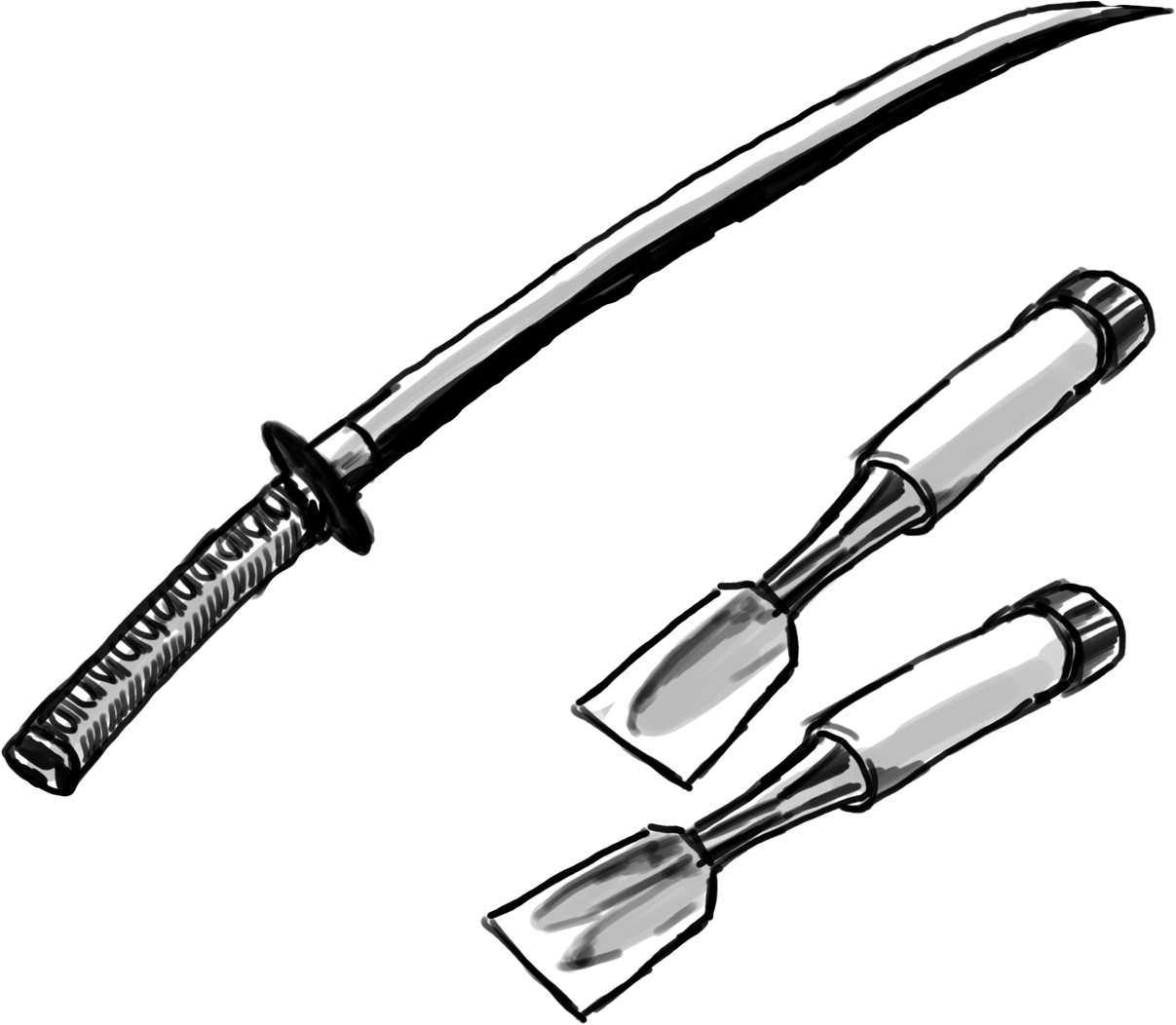

When katana (Japanese swords) were outlawed by the government at the beginning of the Meiji era (1868-1912), the skills of sword smiths were no longer in demand. Some sword smiths decided to use their skills to make chisels and plane blades.

cutting edge of blade

a pull stroke

One of the skills was to make chisels by laminating hard steel to softer iron. The hard steel is for the sharpness of the cutting edge and the soft iron is for strength and flexibility.

After the two metals are combined and shaped, the steel is hardened and tempered. The back of the blade is hollowed* so that flattening can be done faster. The same thing is done for plane blades. It is said that a blade cuts well when the flat distance between the hollow and the edge is minimal.

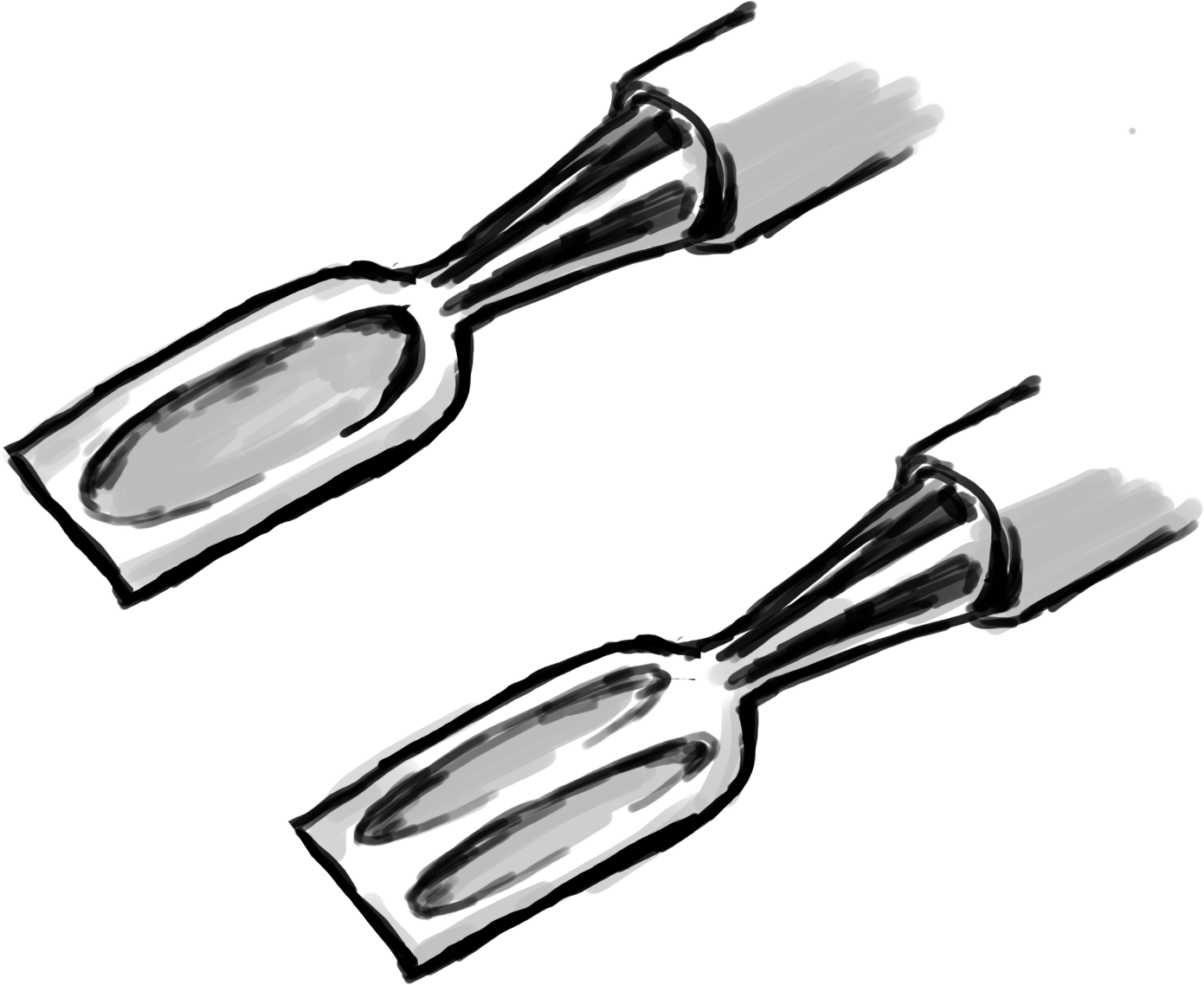

Single hollow vs. multiple hollow

The back of a chisel has a hollow to make the flattening process easier by minimizing the area that needs to be flat. Whether a chisel comes with a single or multiple hollow, it will not have an effect on the cutting edge.

A multiple hollow chisel has extra flats so it will be slightly easier to make straight cuts, particularly when paring past an edge. But because there are extra flats, it takes a bit more time to flatten the back. Some woodworkers like the multiple hollow style simply for its beautiful design.