AOGAMI VS. SHIROGAMI

What's Aogami?

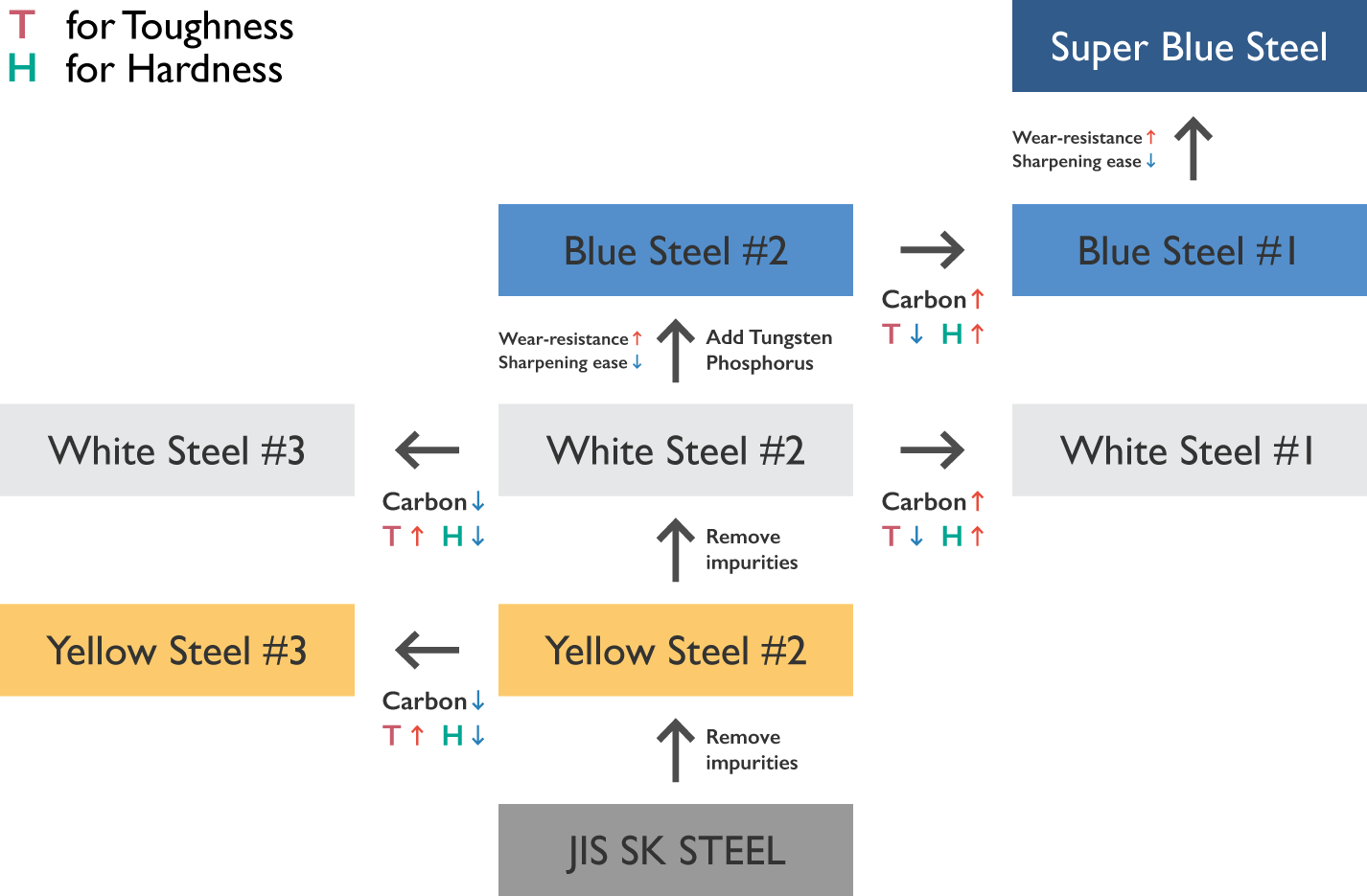

Blue steel (also known as “blue paper steel”, named for the wrapping used by its manufacturer) also contains very little P and S, but W (tungsten) and Cr (Chromium) are added to make the hardening temperature less critical and to increase wear resistance for longer- lasting sharpness.

There are two grades of blue steel with different carbon contents: #1 (1.2-1.4% C) and #2 (1.0-1.2% C). There is one more type called the Super Blue Steel, with more W and Cr, plus Mo (molybdenum) for additional toughness and wear resistance. This also widens the hardening step; it can be cooled in oil instead of water.

In the power grinding steps of manufacture, the white and blue steels can be distinguished by their sparks. White steel produces many bright sparks, but blue steel produces fewer, smaller sparks.

What's Shirogami?

White steel (also known as “white paper steel”, named for the wrapping used by its manufacturer) is used to make tools that can be sharpened to an excellent edge with good quality natural stones.

It is a carbon steel with only very small amounts of the impurities P (phosphorus) and S (sulfur). It has a very narrow range of temperatures for hardening (Yakiire and quenching), and thus requires the blacksmith to be very skilled.

There are three forms of white steel with different carbon contents:

#1 (1.2- 1.4% C)

#2 (1.0-1.2% C)

#3 (0.8-0.9%)

What's Kigami?

Yellow steel (also known as “yellow paper steel”, named for the wrapping used by its manufacturer) contains fewer impurities than the JIS SK steel, and are commonly used for saw blades and kitchen knives.

JIS SK Steel

JIS (Japanese Industrial Standard) SK steel contains a lot of P, S and other impurities but is very easy to temper, thus commonly used for manufacturing knives and tools that can be sold at a low price.