ABOUT WATERSTONES

what's a waterstone?

Man-made sharpening stones are made of synthetic abrasives such as silicon carbide, diamond powder, oxides of aluminum, chromium, magnesium, and cesium, or natural stone powder (honyama-do).

These are combined in proprietary mixtures with binder ingredients and fired to form rigid blocks. The harder versions are often referred to as "ceramic," although in fact, all are ceramic products.

In Japan, the most popular brands are King and Bester. Natural finishing stones are cut from strata of sedimentary rock, and those of highest quality are composed of very uniform fine particles.

SHARPENING PROCEDURE

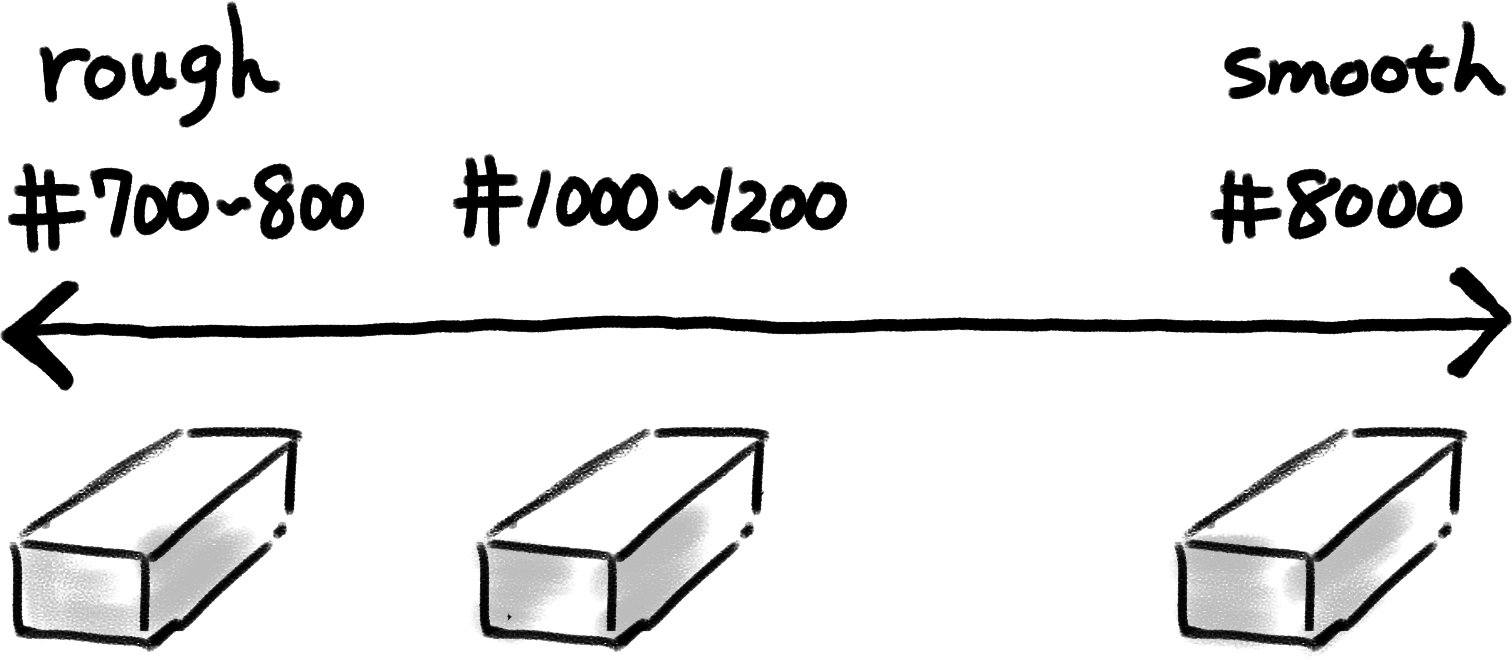

If the cutting edge is nicked, correct the flaws with a 700 or 800 grit stone; then sharpen on a 1000 or 1200 grit stone until the entire bevel meets the flat surface at the cutting edge. Refine the cutting edge by polishing on successively finer stones, such as the King S (6000), Takenoko (7000), and King Gold (8000), or natural finishing stones. Use these stones also to remove the wire edge that forms as the bevel is sharpened and polished, keeping the back of the tool flat on the stone.

The nagura stone, a soft natural or man-made stone, is used to add additional polishing material to the surface of the finishing stone, and to remove occasional larger particles from the surface of natural finishing stones.

HOW TO CARE FOR A WATERSTONE

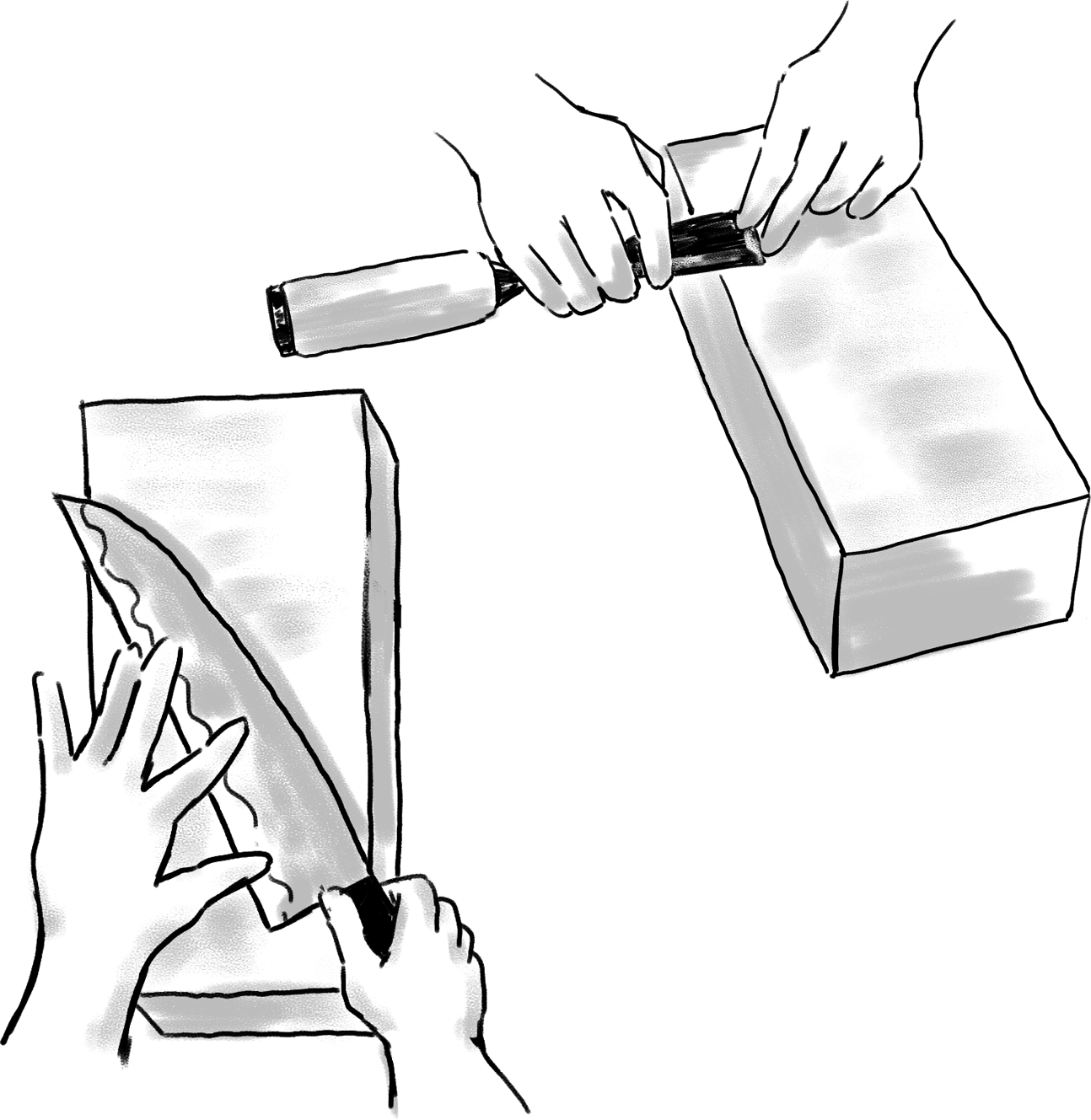

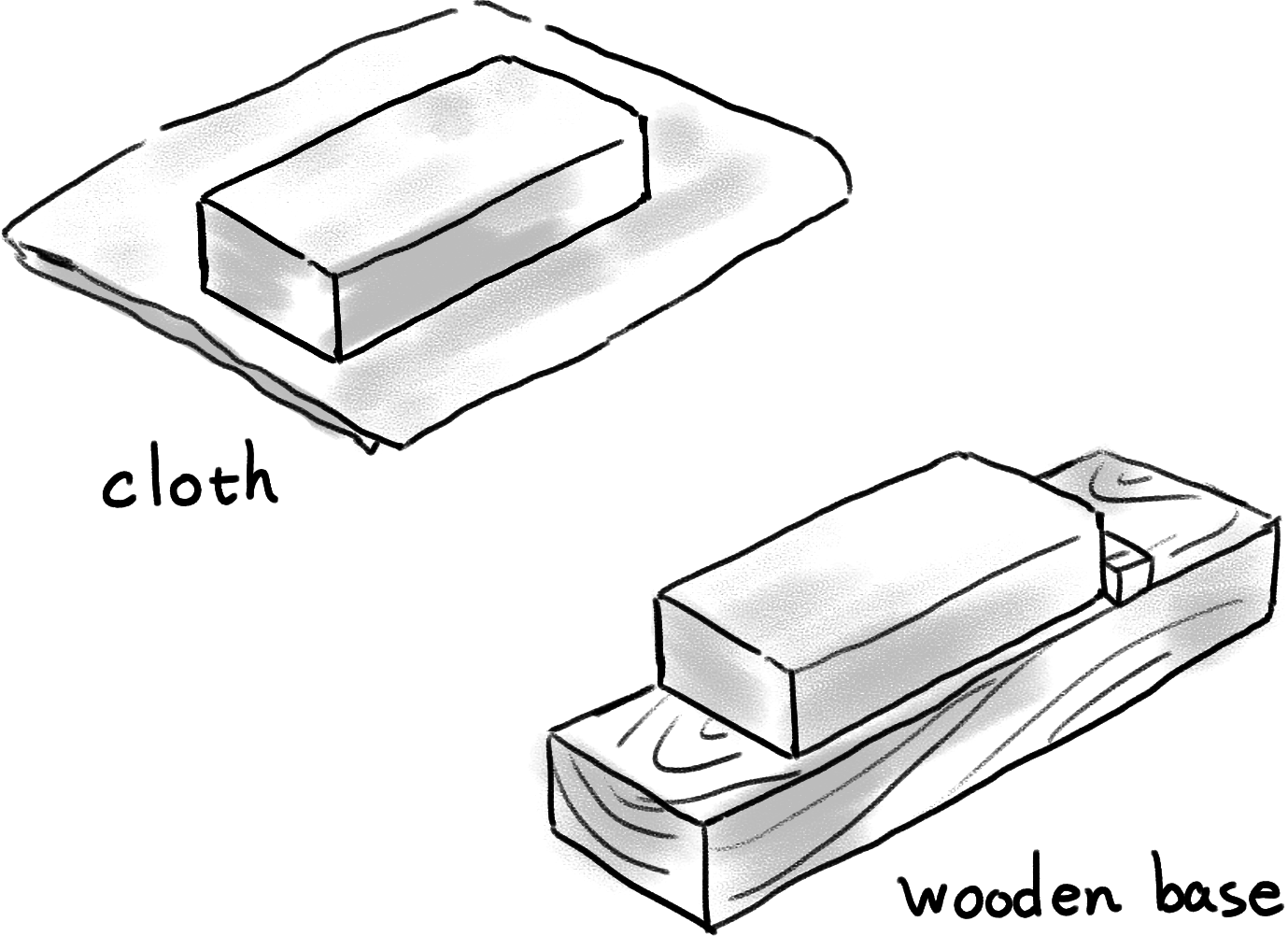

Before using the stone, submerge it completely in water until it is saturated. Ensure stability of the stone with a wet cloth or a wooden base to hold the stone steady as you work. While sharpening, be sure to retain the paste of stone particles that contributes to the sharpening process; wash it off the tool only before proceeding to the next finer stone.

FLATTENING THE STONE SURFACE

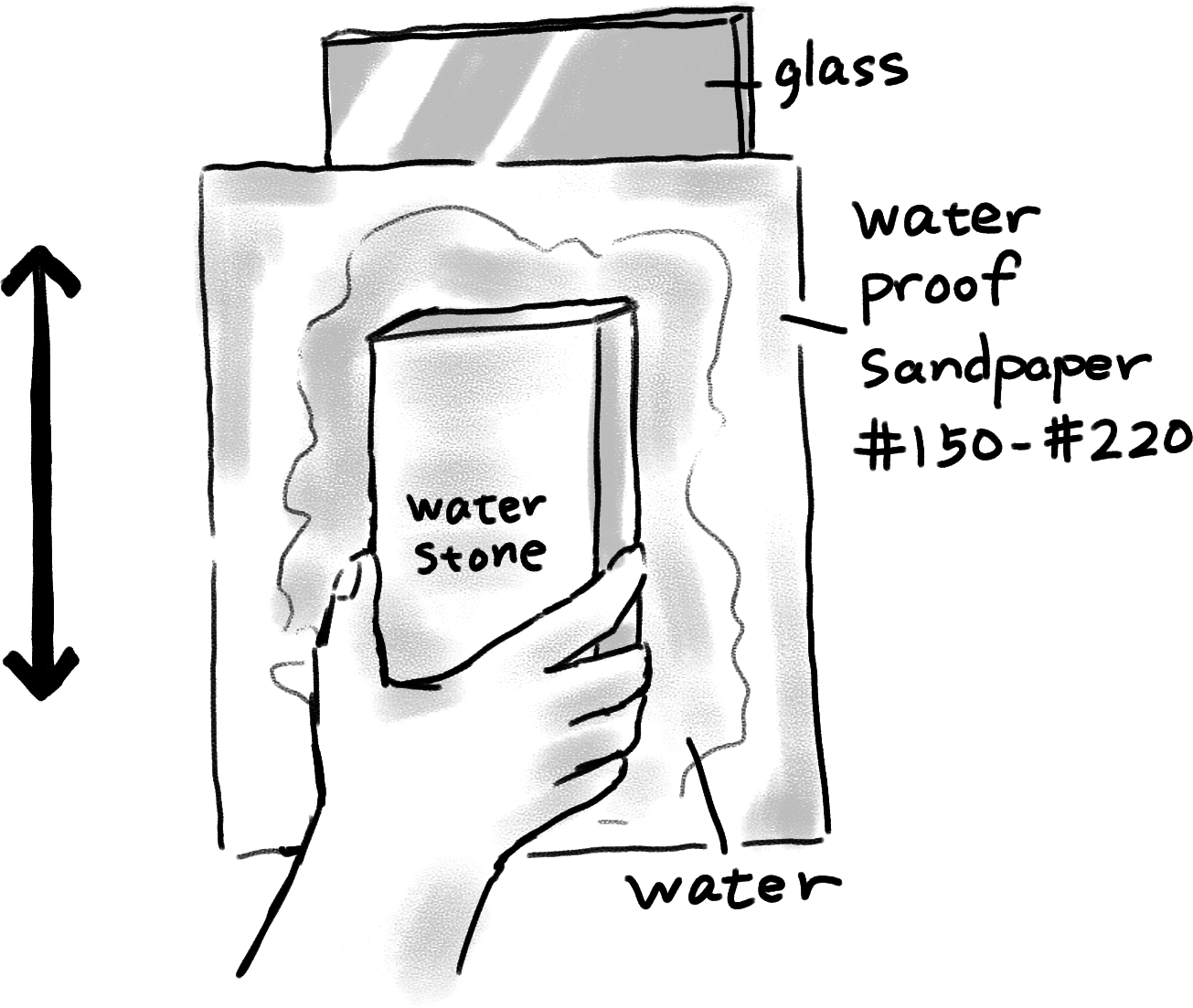

Check the stone for flatness before using, and remove any high areas by rubbing the stone on a flat abrasive surface, such as a flat concrete building block with fine sand on the surface, or moistened 150-220 grit wet-or-dry abrasive paper on a flat steel or glass plate.

NATURAL vs. MAN-MADE STONES

The natural stone is without a doubt the best stone for the finish-sharpening of high-quality tools. It will provide a keener, longer-lasting edge than any man-made stone. However, the man-made stones, available at a lower price, are quite adequate for the coarse and medium sharpening steps, and for finishing the tools of beginning and intermediate woodworkers.

Both our natural and man-made stones will give you a sharper and longer-lasting edge than conventional oil stones, and thus are a wise investment to produce the edges needed for superior work.